Automatic process control system, MES, ERP

One of the main branch of activities of EIC "Technomir" engineering and implementation center is development and implementation of automated control systems of technological processes and manufactures (APCS), telemetry systems, manufacturing execution systems (MES) and enterprise resource planning systems (ERP).

One of the main branch of activities of EIC "Technomir" engineering and implementation center is development and implementation of automated control systems of technological processes and manufactures (APCS), telemetry systems, manufacturing execution systems (MES) and enterprise resource planning systems (ERP).

Complex implementation of automation system data is a powerful tool for creation of a multilevel planning system, administration, metering, analysis and optimization of whole manufacture, and as a sequence, productivity enhancement.

The introduction of these systems by our company is aimed at improving the production processes of the oil and gas industry in accordance with the latest innovations in technical progress, creating comfortable and safe working conditions, bringing the industry to a new level by international standards.

EIC "Technomir" possesses all necessary licenses and permissions to execute theses tasks.

The specialists of the company have experience with software products of the world leading manufacturers:

- «SIEMENS AG» - (PCS7, TIA Portal, WinCC, STEP7, WinCC OA, SIMATIC IT, SINAUT ST7);

- «Allen-Bradley» - (RSLoqix, FT View Studio);

- «Schneider Electric» - (Unity Pro, Vijeo Designer, VijeoCitect);

- «Wonderware» - (InTouch, System Platform);

- «Yokogawa Electric» - (CENTUM VP, ProSafe-RS);

- «Emerson Process Management» - (DeltaV, Open Enterprise, ROCLINK, DS800 Development Suite, Config600, BSI Config);

- «General Electric» - (Logic Developer PLC, View Development).

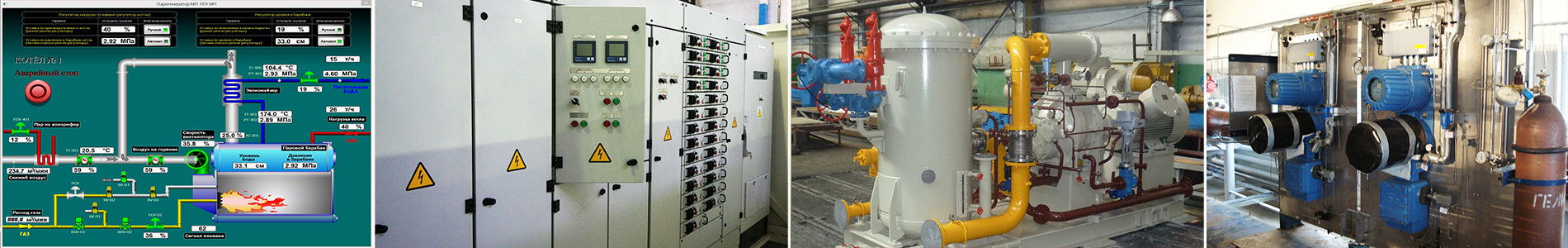

Automatic process control system of technological processes (APCS TP)

APCS TP is created to ensure the uninterrupted operation of the facility with the least technological and operational costs, as well as to solve the problems of planning, control, accounting, analysis and management of production and economic activities.

As a result, the following procedures (operations) are provided:

As a result, the following procedures (operations) are provided:

- automatic and automated process control

- control of parameters of technological processes;

- control and management of operating modes of process equipment;

- preventive and pre-alarm signaling, registration and recording of deviations of technological parameters from regulatory norms;

- protection and blocking of the process equipment;

- regulating of separate technological parameters;

- remote control of the actuators;

- accounting of the operating time of technological equipment

- formation and maintenance of information

databases; - archiving of information about the process;

- formation and display of video frames on the automated workplaces;

- formation and printing of accounting documents;

- diagnostics of the state of the complex of technical means of the system;

- the exchange of information between the levels of the system, as well as adjacent subsystems.

By type of management operations are divided into:

- automatic, developed and performed without participation of technological personnel;

- automated (remote), associated with the management of mechanisms that are performed by personnel from an automated workstation (AWS) using a keyboard and mouse;

- manual (manual), associated with the management of individual drives, switches and mechanisms that are performed by personnel at the location of the equipment using keys and buttons.

The process control system is built with the use of complete automation cabinets based on programmable logic controllers, which are the "brain" of the entire system.

EIC "Technomir" has the necessary production facilities for assembling control and control cabinets, configuring and setting up controllers, assembling cabinets for energy-saving systems.

Simatic WinCC Open Architecture (WinCC OA) is a multifunctional SCADA system

The WinCC OA software is designed for use in large, complex applications that require increased scalability, reliability, and security requirements, as well as requiring special user functions.

WinCC OA allows working with great amounts of data in configurations with significant limitations for hardware resources, and also has the SIL3 certificate, which makes it a unique choice within increased security requirements.

The system is functionally divided into several independent managers (processes), the distribution of which is possible on different computers. Communications between managers are carried out by events. Such a system architecture allows applying it in applications with more than 10 million data points. In distributed systems, up to 2048 servers can be used. Hot backup of servers is supported by automatic client switching and synchronization of process display and historical data.

WinCC OA is a multiplatform system. It supports Windows 7 / Windows Server 2008 (32/64 bit), Red Hat Linux 5 (32/64 bit), OpenSuse 12.1 (32/64 bit), Sun Solaris 10. It is possible to use different operating systems in servers and clients. As a database, you can use either your own storage system or a commercial Oracle 10g / 11g database, an OLE-DB provider is available to access the data. The virtualization platform VMwareESXiServer is supported.

SNMP is used to monitor the network infrastructure.

Special functions and add-ons WinCC OA:

- Video - allows integrating video monitoring systems into the Win CC OA project, which simplifies the work of staff;

- GIS Viewer - integration of standard maps of GIS systems. Mapping of WinCC OA objects;

- Disaster Recovery System - backup control center;

- Communication Center - transfer of alarms to SMS, email, fax, telephone (using a speech synthesizer);

- Report - generation of reports in MS Excel, publication on the Web;

- Recipes - recipe management, import / export to CSV;

- Scheduler - task scheduler with graphical interface;

- Secure - encryption of communications based on Kerberos;

- Advanced Maintenance Suite - technical maintenance management;

- BACnet - interface for building automation systems;

- SIL3 - SIL3 certification according to IEC61508.

Scope of application WinCC OA:

- oil and gas complexes;

- traffic management;

- power engineering;

- water supply / water treatment;

- airport automation;

- scientific research.

Telemechanics systems

Telemechanics is designed to perform the functions of transmitting information about the status of automation objects and the transfer of commands for the dispatching control of the equipment of these facilities. Telemechanics devices in combination with communication channels form a telemechanics system that allows performing these functions at a distance. The transfer of commands from operational personnel (operators) or automatic control devices to control the equipment of automation objects and transmission of information about the state of equipment of these objects in the opposite direction are automatically carried out through the communication channel.

Telemechanics systems include devices for cyclic interrogation of automation objects, comparison of measured values with preset values, control over the operation mode of equipment, as well as transfer of commands for controlling equipment and verifying their performance. Execution of these functions of the system allows the dispatcher to have operative information about the mode of operation of the automation object and, if necessary, actively intervene in its modification.

MES (Manufacturing Execution System) - System of operational management of production

MES is a dynamic information system that manages the effective execution of production operations. Using accurate current data, MES regulates, initiates and logs the operation of the enterprise as events occur. A set of MES functions allows managing production operations from the moment the order appears in the factory to the delivery of the ready product. MES provides the most important information about production activities for the entire organization and the entire supply chain through bilateral interaction. With the use of the MES system, from the point of view of production management, the following tasks are solved.

The key functions of the system are:

- use of current data;

- execution of production operations.

The fundamental difference between MES and SCADA systems lies in the plane of production operations, for the performance of which it is required to control the operation of many units of equipment in various production areas. In this case, usually in the SCADA system, the model of the controlled process is not explicitly specified. The presence of a large number of equipment, relationships and hidden rules makes it necessary to create an explicit production model that underlies the MES system and is an integral part of it.

With the use of the MES system, from the point of view of production management, the following tasks are solved:

- construction of the whole production model;

- orders management;

- accounting of materials;

- the account of the working personnel;

- accounting for downtime and equipment operation;

- the organization of data exchange in the MES system;

- Monitoring the progress of the process and many others.

ERP (Enterprise Resource Planning) Enterprise Resource Planning

ERP is a corporate information system for automation of planning, accounting, control and analysis of all the main processes of the enterprise, ensuring a continuous optimization of the resources of the units and the enterprise as a whole. ERP-system helps to integrate all the departments and functions of the company into a single system, with all departments working with a single database and easier for them to exchange different kinds of information among themselves.

The implementation of the ERP system at the enterprise is rather complicated. Integration of ERP into the company's processes involves a serious change in the logic of internal procedures in the company, the reengineering of business processes, as well as significant changes in the work of its employees.

Main opportunities:

- effective planning of requirements for materials and components, terms and volumes of deliveries;

- regulation of product availability (surplus, deficit), reduction of storage costs;

- regulation of production processes;

- optimization, reduction of material costs;

- control the supply of products and quality of service.

Positive sides:

- timely replenishment of material and technical resources;

- reduction of illiquid stocks and unplanned purchases;

- increase of production volumes;

- control of the consumption of materials;

- increasing the effectiveness of pricing;

- reduction of labor costs.