Pumping stations

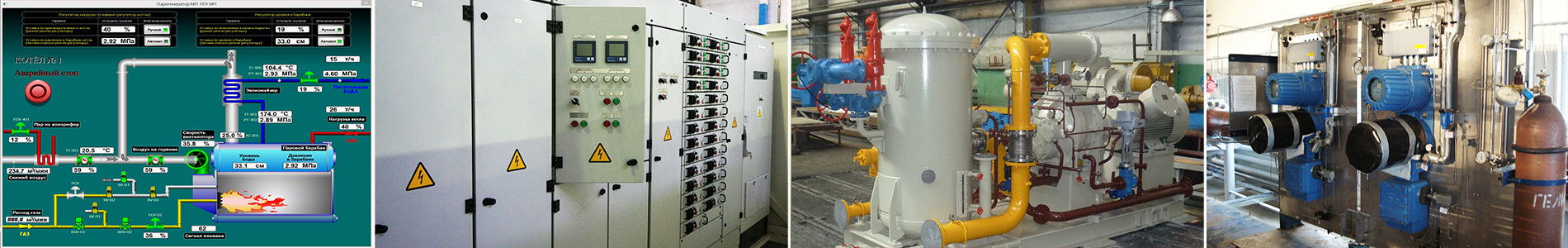

One of the activities of the EIC "Technomir" is the manufacture of block pumping stations for various purposes.

Block pump stations (BPS) are designed for pouring and pumping the liquids, in oil collection and treatment systems, fire fighting, water supply. The stations are carried out in the form of separate block-boxes, for sending by rail or by road, which are mounted in a single building on the site of operation. Blocks have a complete internal wiring of instruments and equipment.

The composition of the BPS includes:

- block-box with life support systems (ventilation, heating, fire alarm and fire extinguishing, lighting);

- pumps;

- shut-off and control valves;

- piping;

- Instrumentation equipment;

- service areas;

- cable products for interblock installation.

At the request of the Customer, the pump station may include:

- the block hardware;

- the switchgear unit;

- block of the ventilation chamber.

The walls and roof of the block pumping stations are made of sandwich panels. The base of the block pumping stations is made of high-quality steel and insulated with mineral wool plates.

At the request of the Customer, the BPS can be equipped with a system for automating the operation of technological equipment, which provides:

- the work of the station without the constant presence of maintenance personnel;

- manual local control of pumps, fans, electric heaters, latches;

- automatic control of technological parameters of pumps, electric motors (flow rate, pressure, temperature, vibration level, motor current, etc.);

- automatic activation of electrical protection and alarm.

Automation system provides automatic accounting, control and transmission to the control center of the following parameters:

- pressure of the pumped liquid at the inlet and outlet of each pump;

- Monitoring filter clogging on the suction line;

- temperature of the pumped liquid;

- the account of the consumed electric power;

- the state of shut-off and regulating electric drive armature;

- the state of the main and reserve pumping units;

- air temperature in the room;

- control of gas contamination;

- vibration of the pumping unit.

EIC "Technomir" produces the following pumping stations:

- block pumping stations for pumping oil;

- block cluster pumping stations;

- block pumping stations for pumping of burning fuel oil;

- block pump stations of fire extinguishing.

The installations are manufactured for all climatic zones and zones of all explosion hazard classes

The installations are manufactured for all climatic zones and zones of all explosion hazard classes

Delivery of block pumping stations is carried out complete with design documentation, passports and documentation for materials, components and equipment supplied by the manufacturers.

In 2016 specialists of the EIC "Technomir" designed, manufactured, delivered and put into operation a pumping station for pumping fuel oil as part of a complex of block-modular equipment installations for the production of diesel fuel (IPDF) at the Yaraktinskoye oil and gas condensate field (YANGKM). Customer: OOO Irkutsk Oil Company.

The pump station includes a block-box with life-support systems (ventilation, heating, fire alarm and fire extinguishing, lighting), hermetic centrifugal sealless pumps with built-in explosion-proof shielded electric motor (HERMETIC-Pumpen GmbH), shut-off valves (OAO BAZ , ZAO Splav-M, OOO Energoresurs), a filter (ZAO Rust-95), instrumentation equipment (Emerson Process Management, WIKA, OOO Valcom, Tomsk Electronic Company), explosion-proof boxes, posts management (OAO VELAN), piping arrangement.