Compressor units

One of the main directions in solving the problem of reducing the flaring of associated petroleum gas (APG) with its subsequent disposal is the need to create modern highly reliable fully automated block-modular compressor units designed specifically for transport from fields to gas processing plants.

One of the main directions in solving the problem of reducing the flaring of associated petroleum gas (APG) with its subsequent disposal is the need to create modern highly reliable fully automated block-modular compressor units designed specifically for transport from fields to gas processing plants.

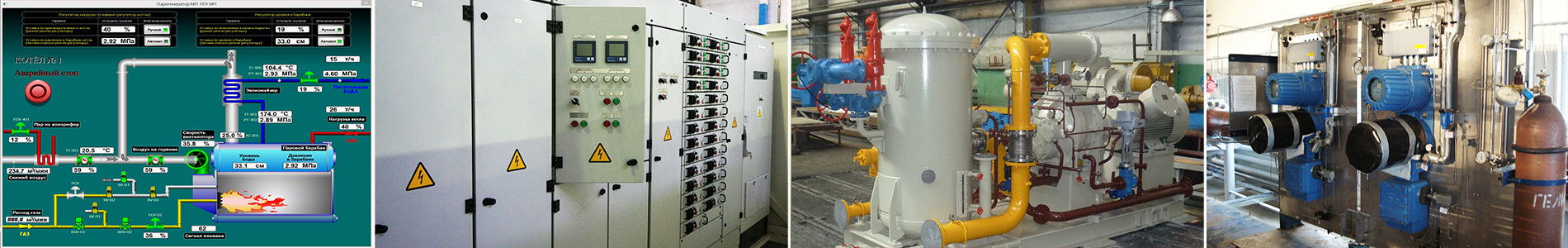

The company specializes in creating block-modular automated screw compressor units for oil and gas, chemical, metallurgical food and other industries in individual orders.

The company carries out a full cycle of works beginning from the search for technical solutions up to the commissioning of the compressor plant.

What is included in the work:

- Development of design documentation for compressor and refrigeration equipment based on screw compressors for operation in various climatic zones.

- Organization of manufacturing and carrying out preliminary tests at the factory and acceptance and commissioning tests at the Customer's facilities.

- Chef-installation works, start-up and adjustment works on the site of operation;

- Training of maintenance personnel;

- Author's supervision of the operation of compressor units.

The project is implemented using the developed complete package of engineering programs for the calculation of screw compressors, which, in combination with the process of automated design, shortens the terms of the working project and increases its quality.

At the request of the Customer, the components of foreign companies are used.

When creating new compressor units, special attention is paid to the issues of the operational control of the quality of the units assembly, as well as to the issues of carrying out complete tests of compressor units that are close to the operating conditions at the manufacturer's stand with the participation of the Customer's representative.

When creating new compressor units, special attention is paid to the issues of the operational control of the quality of the units assembly, as well as to the issues of carrying out complete tests of compressor units that are close to the operating conditions at the manufacturer's stand with the participation of the Customer's representative.

Unified, blocked, automated compressor units with a screw compressor oil-filled or dry type are designed for work in the oil and gas industry, as well as in oil refining and chemical enterprises.

The main features of this series of compressors:

- the possibility of a flexible and wide choice of compressor equipment for the development of deposits and the replacement of obsolete equipment;

- the possibility of operating compressor plants when compressing a hydrocarbon gas of a wide fractional composition due to the introduction of separate lubrication systems and injection into the compressor;

- full automation of all systems of the installation;

- regulation of productivity by a slide valve in the range of 100-10%;

- being supplied in two climatic versions: BC4 (boreal climate) (for indoor use) and BC1 (in a container).

The screw compressor is equipped with:

- seals separating the bearing cavities from the flowing part;

- vibration instrumentation control for the reliability of bearing units.

Start and stop in unloaded automatic mode. Cooling of oil and gas is carried out by devices of air or water cooling. The quality of the compressed gas at the outlet from the compressor plant is provided by an oil separator and a separator, which ensure that the residual oil content in the gas is within 3 ÷ 5 mg/m3.

Delivery of compressor units is carried out ready-to-use units complete with inter-block pipelines.